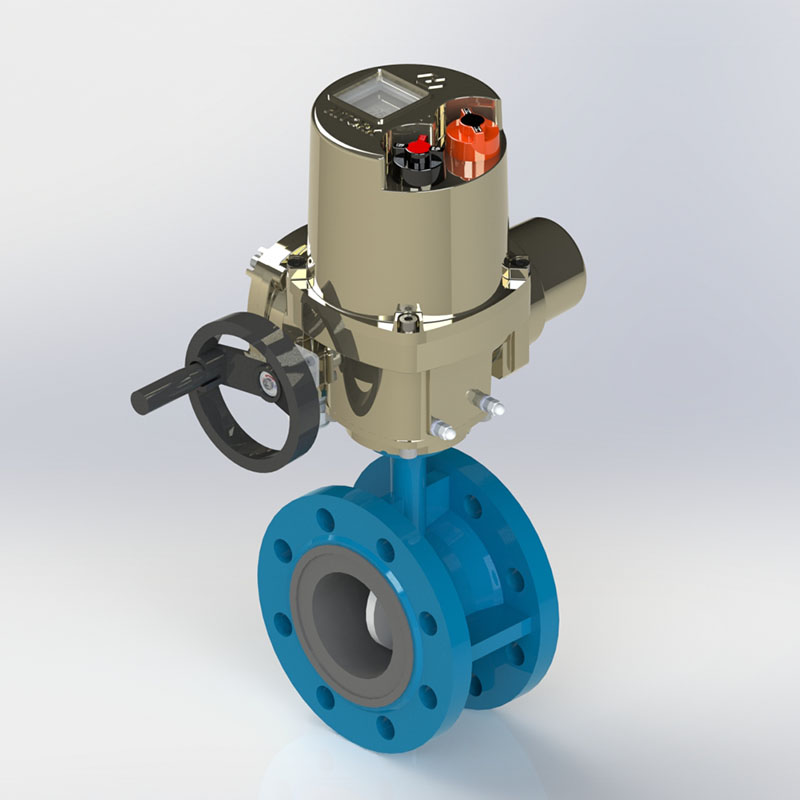

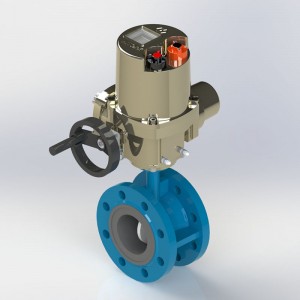

Flanged Ruber Lined Butterfly Valve

Product Introduction

The lined butterfly valve has simple structure, light weight, good sealing performance and long service life. It is usually used foron-off conditions and can also be used for regulate. It is widely used in various corrosive occasions such as acids, alkalis, and salts. Among them, the butterfly valve specially developed for desulfurization and denitration in the thermal power industry adopts a pinless structure with a bottom rotation, the center position of the valve plate is more accurate, and the sealing performance is better; the valve plate is made of 2507 or 1.4529 material, which has greatly improved corrosion resistance as well as anti-abrasion performance.

Product Advantages

Wafer&Flange connection, simple structure, compact, light weight, can be installed in any position.

Pinless connection, zero leakage.

Small flow resistance coefficient, large circulation capacity, good regulating.

Axial thrust bearing or lubricated bronze to prevent overload of valve stem.

Valve body: Cast iron, nodular cast iron, carbon steel, 304/304L/316/316L

Valve seat: NBR/EPDM/PTFE/VITON special rubber of desulfurization

Valve trim: 2507 dual phase steel/1.4529 dual phase steel/Dl/WCB/CF8/CF8M/C954

Valve stem: 2Cr13/304/420/316

Actuator: Electric actuator

Type: Part-turn

Voltage: 110, 200, 220, 240, 380, 400, 415, 440, 480, 500, 550, 660, 690

Control type: on-off

Series: intelligent