HPL

Product Introduction

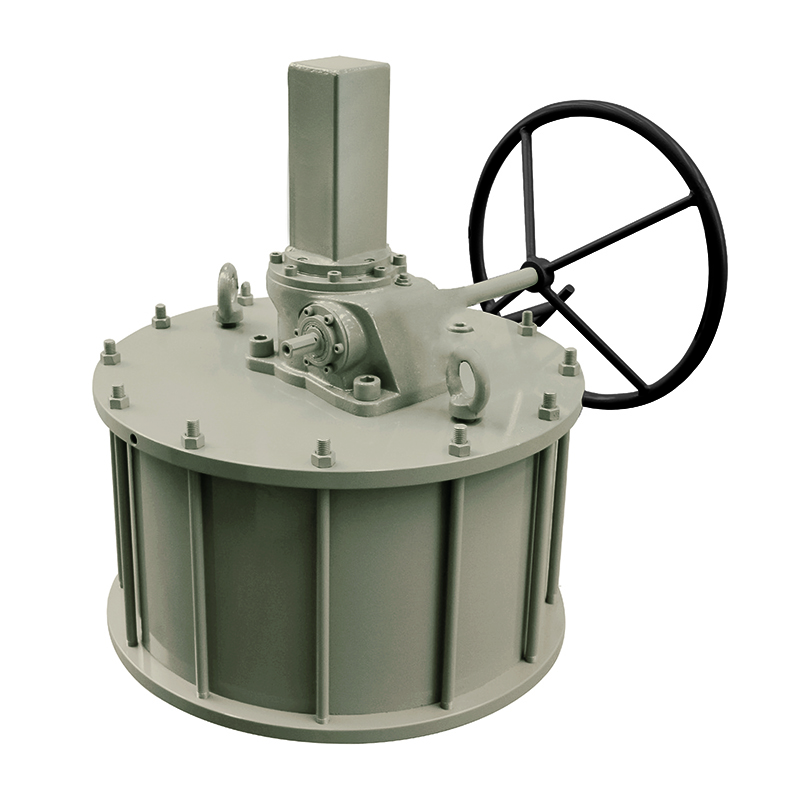

Pneumatic piston actuator refers to an actuator that makes full use of air source pressure to increase the output force of the actuator and reduce its mass and size. The pneumatic piston actuator can be a pneumatic piston linear actuator with a spring reset and zero-proportional adjustable, or it can be a double-acting actuator without a spring. Pneumatic piston actuators are characterized by large output force, simple structure, reliability, light weight, fast action speed and good shock resistance. Pneumatic piston actuators can be combined with straight-way single-double-seat, angle, sleeve, diaphragm, fine and small and other straight-stroke regulating valves and equipped with a positioner to become a pneumatic piston regulating valve. The required allowable pressure difference can be obtained by selecting different spring ranges.

The integrated mounting plate does not require traditional mounting brackets, thereby reducing the number of components that need to be installed.

The manual mechanism adopts the design of worm gear and screw drive.

The pneumatic actuator has a lubrication system, which can provide very smooth valve control.

The sealing ring and guide ring ensure that even if the cylinder piston rod is subjected to directional force, the piston and the metal surface of the inner wall of the cylinder will not directly rub against.

The stroke limit and manual device can be used for almost any control valve application.

Rugged aluminum alloy and cast steel structure provide better stability and corrosion resistance.