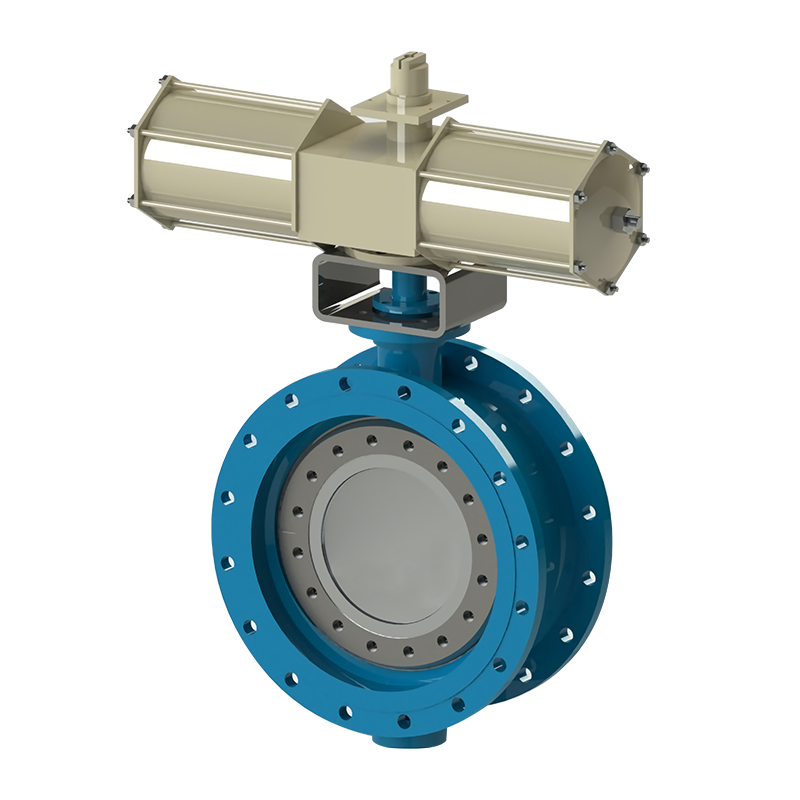

Scotch York Butterfly Valve

Product Introduction

The valve stem axis deviates from the center of the disc and the center of the body at the same time, and the rotation axis of the valve seat has a certain angle with the axis of the valve body pipeline, which is called a triple offset butterfly valve. The scope of application of the triple offset butterfly valve can withstand pressure up to 2500lb, temperature resistance as low as -196℃, up to 700℃, sealing up to 0 leakage, and control ratio as high as 100:1. It means in all kinds of harsh and critical process control pipelines, whether it is an on-off valve or a control valve, as long as the type is properly selected, the butterfly valve can be safely used, and the cost is relatively low.

Product Advantages

‘Cam- action' and ‘right angled' conical sealing design ensures that the metal sealing components are never in contact until their final degree of closing - this results in repeatable sealing and a vastly extended valve life.

Metal-to- Metal sealing ensures bubble - tight shut-off, resulting in zero-leakage performance.

Suitability to harsh media - construction of the valve features no elastomers or materials typically affected by corrosion .

Geometric design of sealing components provides friction - free stroking throughout the valve. This extends the valve life and allows a lower - torque actuator to be fitted.

There are no cavities between sealing components, resulting in no clogging, low maintenance and extended valve life.

Valve body: WCB, WC6, WC9, CF8, CF8M

Valve stem: 2Cr13, 25Cr2MoV, 06Cr19Ni10, 0Cr17Ni12Mo2

Valve trim: WCB, WC6, WC9, CF8, CF8M

Packing: A182 F304, A182 F316

Actuator: Pneumatic actuator

Type: Scotch Yoke

Voltage: 24, 110, 220